A 20-year partnership

For more than two decades, Wilson Transformer Company has been working with Nynas to provide top performing transformer solutions to customers in Australia and around the world.

For more than two decades, Wilson Transformer Company has been working with Nynas to provide top performing transformer solutions to customers in Australia and around the world.

Case story

A family company from the very start, Wilson Transformer Company (WTC) has grown to become Australia’s largest manufacturer of power and distribution transformers. Today, WTC is run by Robert Wilson, Executive Chairman (left) and his son Ed Wilson, Managing Director (right).

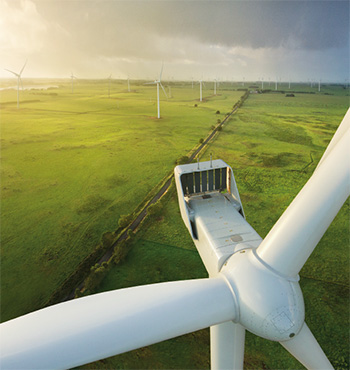

With a population of 7.5 million, New South Wales is Australia’s most populous state and home to the country’s largest city, Sydney. In the north-eastern part of the state, the 75-turbine Sapphire Wind Farm is currently being constructed to provide clean wind energy that will power 115,000 homes.

Wilson Transformer Company (WTC) delivered the power transformers for this important project. Established in 1933, WTC is the largest manufacturer of power and distribution transformers in Australia. The company has thousands of transformers operating all over the country and many other parts of the world. Its products delivered power to the London Olympics and continue to operate the Euro Tunnel.

“For the Sapphire Wind Farm, we’ve supplied two 190MVA 330/33kV power transformers, which are among the larger power transformers we’ve manufactured for the renewable sector,” says Ed Wilson, Managing Director of WTC.

Having started in January 2017 and expected to be completed during the second half of 2018, the project has faced a few technical challenges and transport constraints, not least transporting the 110-tonne transformers by road.

“Due to the physical dimensions of the units, one of the bridges on the way had to be upgraded to handle the weight and size of the transformer. Transformers of this dimension are transported disassembled with the accessories delivered separately for final assembly at site,” explains Ed Wilson.

As with many other projects in the past, WTC chose Nynas as the supplier of insulating oil for the Sapphire Wind Farm.

“Transformer oil is a critical component for the transformer cooling and insulation system, so we impose strict requirements applicable to all insulating oil in the supply chain.”

The total volume of oil used in the two power transformers was around 110,000 litres. The naphthenic oil was delivered to the site with test certificates for each batch, and then the final filling process began.

“The excellent cooperation between the Nynas and WTC teams made it possible to achieve a prompt, smooth installation of the units.”

The team could look back on a partnership that has lasted for more than 20 years.

“To support our operations, the supplier’s quality and delivery performance are critical.

We apply a strategic approach in developing supply chain partnerships that provide value to both parties, and this is no different for Nynas,” notes Ed Wilson.

“We value our long-term relationship and share a common vision to provide superior value to our customers by ensuring a total commitment to operational excellence. We look forward to continuing our relationship with Nynas into the future.”

Nynas has the world's widest range of transformer oils – developed to handle just about every conceivable climate, design and operating condition.

See a selection of our transformer oils based on their key characteristics, including viscosity. For more information on each product, simply download the relevant Product and Safety Data Sheets. See all products