Recycling asphalt: science, sustainability, and the road ahead

Asphalt recycling is transforming how roads are built and maintained, reducing costs and cutting CO₂ emissions. At Nynas, Chief Scientist Xiaohu Lu is leading research that turns complex chemistry into practical solutions for longer-lasting, more sustainable roads.

On evening walks after dinner, Xiaohu Lu often stops to inspect the ground beneath his feet. Aiming to hit his 10,000 daily steps, he can’t help but notice cracks or potholes in the pavement.

"I often pull out my phone and start taking pictures – even if my wife sometimes pokes fun at me,” he says with a smile.

For Lu, the Chief Scientist at Nynas who has dedicated his career to probing the hidden complexity of asphalt, each defect is a small puzzle: what caused it, and how might it have been prevented?

“It’s about understanding the forces involved and how the asphalt reacts,” he explains.

More than ‘scrape and re-lay'

Lu’s research on how different binders affect asphalt durability and recyclability sits at the intersection of chemistry, engineering, and sustainability.

Reusing and recycling reclaimed asphalt pavement (RAP) is a sustainable practice common in road construction and maintenance. It minimises environmental impact while also reducing the need for virgin materials, conserving natural resources, and lowering construction costs.

The process may sound straightforward: mill the old road, add some fresh binder, and lay it down again. But there’s far more to it.

“It’s not just putting the old stuff into the new mix,” Lu explains. “As asphalt ages, those bitumen-based binders – the glue that holds stones together – become stiffer, more brittle, and chemically unbalanced.”

One of the central scientific challenges of asphalt recycling is how to restore the properties of aged bitumen. If only softer binder is added, much of the old binder risks remaining inactive inside reclaimed asphalt.

“We want the new and old materials to be wholly compatible,” Lu notes.

The solution often involves rejuvenators: agents designed not only to soften but also to restore the chemistry of aged binder, ensuring that recycled asphalt delivers reliable long-term performance.

However, the growing use of polymer-modified bitumen (PMB) and biogenic binders adds another layer of complexity to the process. Polymers can age differently from bitumen, sometimes even in opposite directions.

“Balancing stiffness is not enough; the chemistry must also be balanced,” says Lu.

This requires understanding how the molecular fractions of bitumen shift over time — and how to bring them back into harmony during recycling.

Research on the road

Turning laboratory insight into practical guidance demands patience and long-term testing. Lu and his colleagues at Nynas are deeply engaged in collaborative projects with industry partners that bring science onto the road.

On the E4 highway outside Nyköping, for example, test sections have been constructed together with Nordic construction company NCC, the Swedish National Road and Transport Research Institute (VTI), and other partners.

These trials, jointly financed by Sweden’s state innovation agency, Vinnova, and the Development Fund of the Swedish Construction Industry (SBUF), combine reclaimed asphalt with a biogenic-containing PMB developed by Nynas.

By monitoring performance under Swedish traffic and climate, the project is building knowledge on durability and recyclability for next-generation binders.

A second project involving VTI and Swedish construction company Skanska tackles the challenge of high-value reuse of reclaimed asphalt pavement containing polymer-modified bitumen.

While PMB has long been used in Sweden, restrictions remain on incorporating its RAP into surface layers due to performance uncertainties.

By collecting and analysing material from PMB road sections of varying age, the project is working toward robust criteria that would enable safe reuse.

“If end-of-life PMB can be reused effectively, the initial investment becomes far more cost-effective over the pavement’s life,” Lu explains.

‘Research isn’t a straight line’

The stakes extend beyond technical performance. Road authorities face the dual challenge of lowering carbon emissions while maintaining reliable infrastructure.

Asphalt recycling is one way to help in those efforts.

“By reusing reclaimed asphalt, CO₂ emissions can be reduced substantially,” says Lu.

“But this must not come at the cost of shorter pavement life. Otherwise, the benefit disappears.”

That long-term view defines Lu’s work — and his optimism.

“Research isn’t a straight line,” he reflects.

“You start with a goal and move step by step: laboratory trials, field sections, monitoring. Sometimes the results are not what was expected, but that too is valuable knowledge.”

It is also what excites him most: the chance to push a traditionally conservative industry forward with science. “I find it very exciting to look at new innovative solutions and then convince people with data that it works,” he says.

Circularity and the road ahead

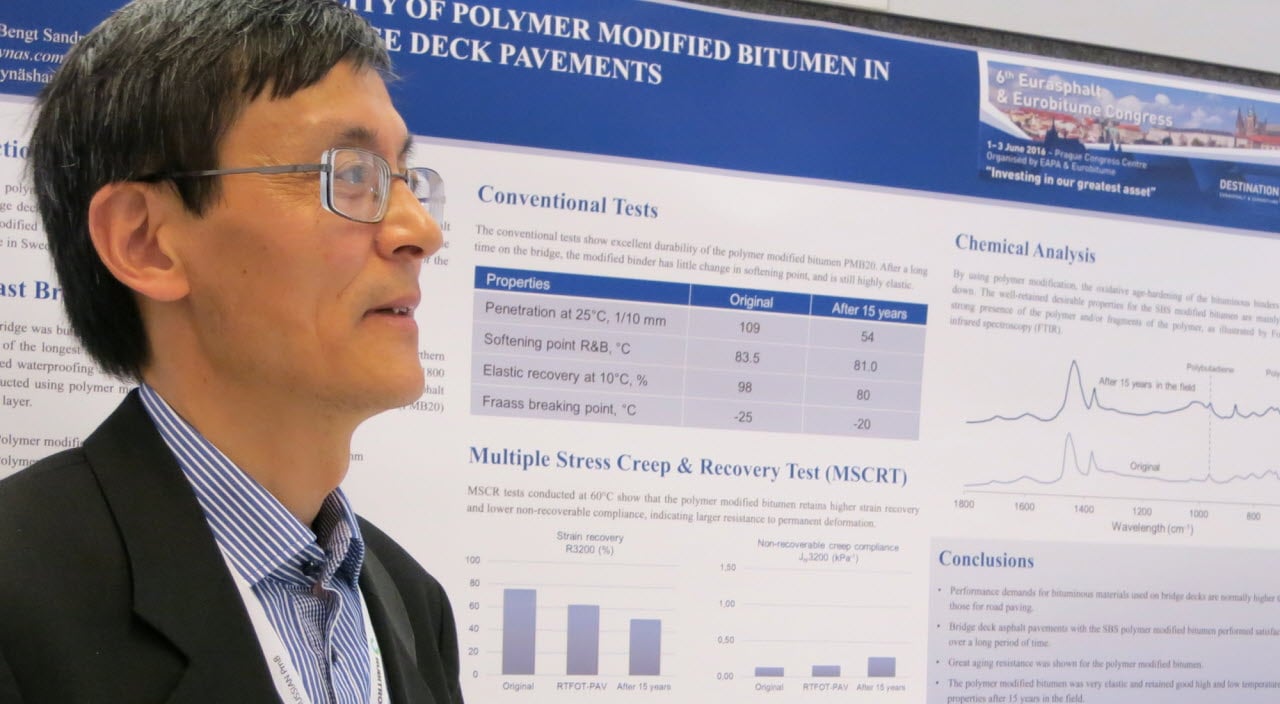

Lu was reminded of the impact of previous asphalt innovation while driving from Sweden to Denmark across the Öresund Bridge on a recent family trip.

“I felt so proud knowing that Nynas’s polymer-modified bitumen had been used on this iconic bridge when it was built 25 years ago,” he recalls.

As he reflects, the scientist in him keeps returning to the same vision — one of roads that last longer, cost less over time, and can be renewed again and again.

“Our role is to turn promising ideas into reliable practice,” he says.

“So that what is built today becomes the foundation for tomorrow’s circular roads.”