Solvency of Nynas base oil vital for increasingly popular Polyurea Grease

Electric vehicles are driving a recent surge of interest in polyurea greases. Perfect for high-performance applications, the production volumes are growing, especially in Japan.

Unique properties such as a high degree of water resistance, high temperature, long life, and low noise make polyurea greases useful for several advanced and challenging applications such as electric vehicles.

So far, production volumes of polyurea greases have been limited, partly because the manufacturing process includes a controlled reaction between highly toxic amines and isocyanates. However, between 2023 and 2024 polyurea greases increased their share of the global grease production volumes from seven to ten percent. Meanwhile, in Japan, the polyurea segment is now exceeding 30 percent of total grease volumes.

“Because of the growing popularity of polyurea greases, we recently decided to investigate what impact some characteristics of the base oil might have on the performance of these greases,” says Mehdi Fathi-Najafi, former Chief Specialist at Nynas AB, now Independent Senior Advisor.

This resulted in an extensive study presented at the 2024 ELGI annual general meeting in Madrid, where it was met with a lot of interest.

“The study confirmed that if Nynas’ naphthenic base oils are used for the manufacturing of polyurea greases, less than seven percent of thickener is required to reach the consistency of NLGI grade 2 grease,” explains Mehdi.

This means that the thickener content can be reduced to almost one third of what is needed when synthetic base oil is used.

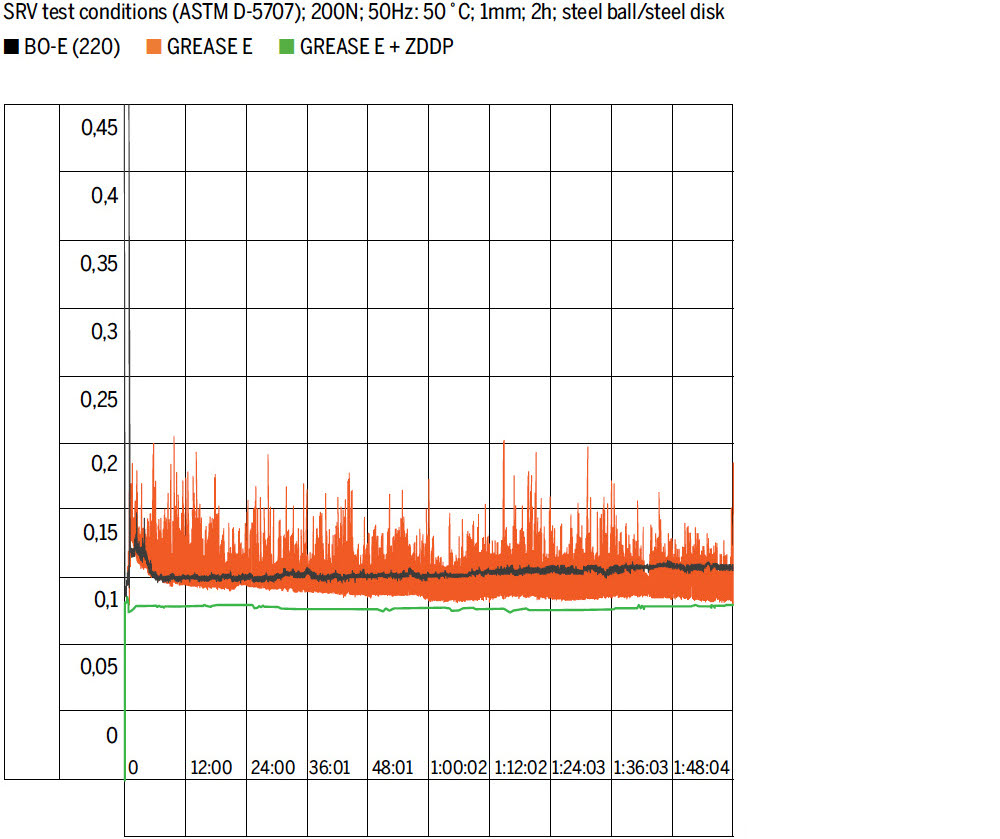

Tribological testing showed that the base oil with the highest degree of solvency resulted in the lowest friction coefficient measured by SVR (Schwingung Reibung Verschleiß) testing machine. This supports findings from an earlier study, suggesting that naphthenic oil compresses faster under applied pressure, resulting in higher pressure viscosity coefficient.

“Polyurea greases provide a perfect example of the importance of starting with a high-quality base oil with excellent solvency. It makes sense and enables more productive and more sustainable grease production,” concludes Mehdi Fathi-Najafi.

Figure 1: Mefa Diagram

Further reading:

The impact of the degree of solvency and viscosity on the performance of the polyurea greases, Eurogrease 2 2024, April/ May/June; L. Muntada, M. Fathi- Najafi and E. Ortega